Transformer supply bottleneck threatens power system stability as load growsTransformer supply bottleneck threatens power system stability as load grows

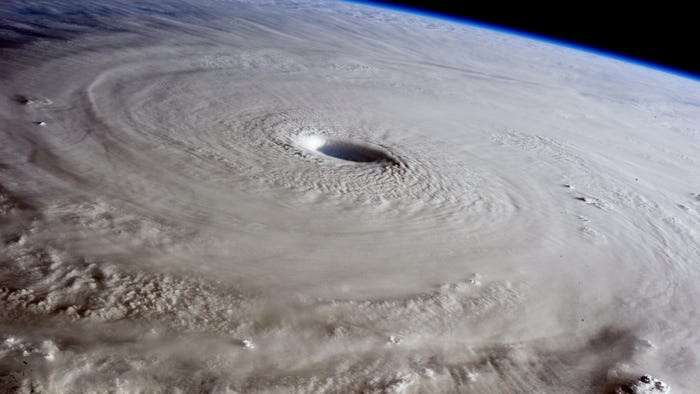

Hurricanes, wildfires and surging demand burden aging transformers, but new ones are unavailable.

The urgently needed modernization of the U.S. power system is being impeded by slow access to vital new electric transformers.

Advanced computing and economy-wide electrification are expected to grow demand almost 16% by 2030, increasing the need for both more and bigger transformers, according to a December National Renewable Energy Laboratory study. And that need is being accentuated where extreme weather events like the Los Angeles wildfires and East Coast hurricanes require rebuilt distribution systems.

But global supply-chain disruptions continue to slow access to the transformers critical to stabilizing power system voltages and efficiency.

“Delivery of a new transformer ordered today could take up to three years,” said National Association of Electrical Manufacturers, or NEMA, Director of Government Relations Peter Ferrell. “Five years ago, that wait time was four to six weeks.”

Faster access to transformers will take time and investment, manufacturers said.

“The short term appears to be painful for the large investment areas” and “projects have been postponed one to two years already,” said Jeffrey DeSain, general manager, North American Transformer Business, for manufacturer Schneider Electric. “It will take a variety of investment de-risking solutions for supply chains and manufacturers to catch up.”

Load growth pressure on existing infrastructure will likely continue for years, and perhaps for a decade or more, manufacturers and analysts say. Meanwhile, transformer supply solutions, like standardizing transformer designs or organizing and funding a reserve supply, will take policymaker cooperation, if they can be implemented at all, many said.

More than 80,000 types of transformers

There are differences in lead times for the many different types of transformers that step up and step down voltages throughout the power system.

At wind and solar projects, small pad-mounted transformers step up voltage to medium- or larger-sized transformers at production-site substations, according to Doug Wolken, Hitachi Energy head of marketing and sales, transformers, North America. Large transformers at natural gas, nuclear, and hydropower plants also step up voltage to the transmission system, he said.

At distribution substations, large pad-mounted transformers step down voltage from the transmission system to medium or small pad mounted transformers, Wolken said. Small pole mounted or pad mounted distribution system transformers step the voltage down for homes and businesses, he said.

The U.S. system had 60 million to 80 million distribution transformers in late 2024, and the 2050 need “could increase by up to 260% compared to 2021 levels,” NREL reported. About 55% of residential transformers are near the end of their lives, with many now more than 40 years old, the lab said.

And there are over 80,000 transformer types throughout the U.S. power system, according to the 2024 National Infrastructure Advisory Council, or NIAC, report from industry stakeholders.

Larger transformer lead times range from 80 to 120 weeks, according to a Wood Mackenzie, or WoodMac, April report. Special electrical steel vital to transformer power loss reductions remains expensive and difficult to obtain domestically, WoodMac said.

To read the complete article, visit Utility Dive.